Description

Microporous Aluminate Molecular Sieve Crystal

A synthetic hydrated silica aluminate (zeolite) or natural zeolite having a molecular sieve function. The chemical formula is (M ′ 2M) O – Al2O3 – xSiO2 – yH2O, where M ′ and M are monovalent and divalent cations such as K+, Na+, Ca2+, Ba2+, etc. It has many uniform pore channels and neatly arranged pores in its structure, and molecular sieves with different pore sizes separate molecules of different sizes and shapes. Based on the different molecular ratios of SiO2 and Al2O3, molecular sieves with different pore sizes have been obtained. Their models include 3A (potassium type A), 4A (sodium type A), 5A (calcium type A), 10Z (calcium type Z), 13Z (sodium type Z), Y (sodium type Y), sodium mordenite, etc.

It has high adsorption capacity, strong selectivity and high temperature resistance. Widely used in organic and petrochemical industries, it is also an excellent adsorbent for gas dehydration. In terms of exhaust gas purification, it is also receiving increasing attention.

Chinese name Molecular sieve Foreign name Molecular sieve

Essence —- a hydrated silica aluminate or natural zeolite

Features – There are many uniform pore channels and cavities

Performance – adsorption, ion exchange, catalytic performance

Application – catalysts, adsorbents

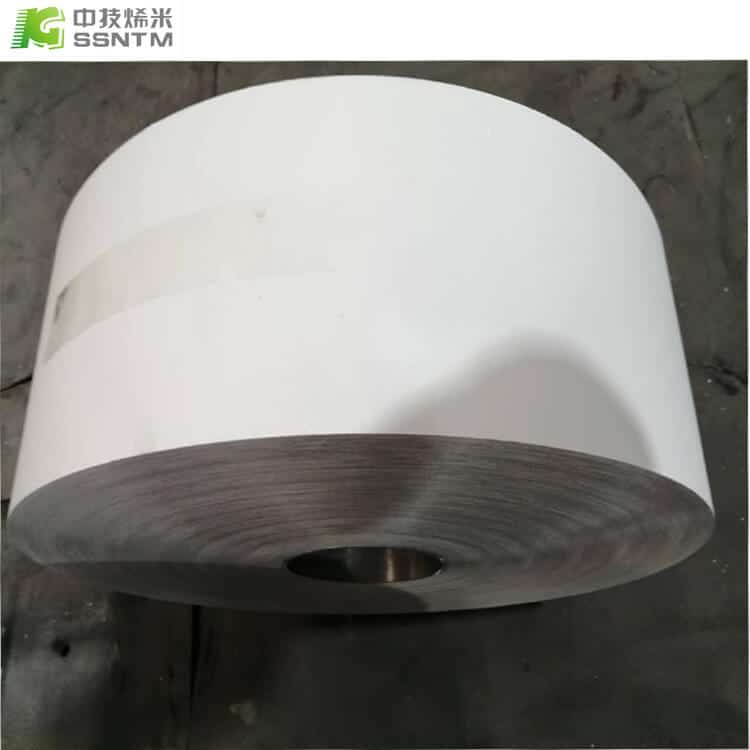

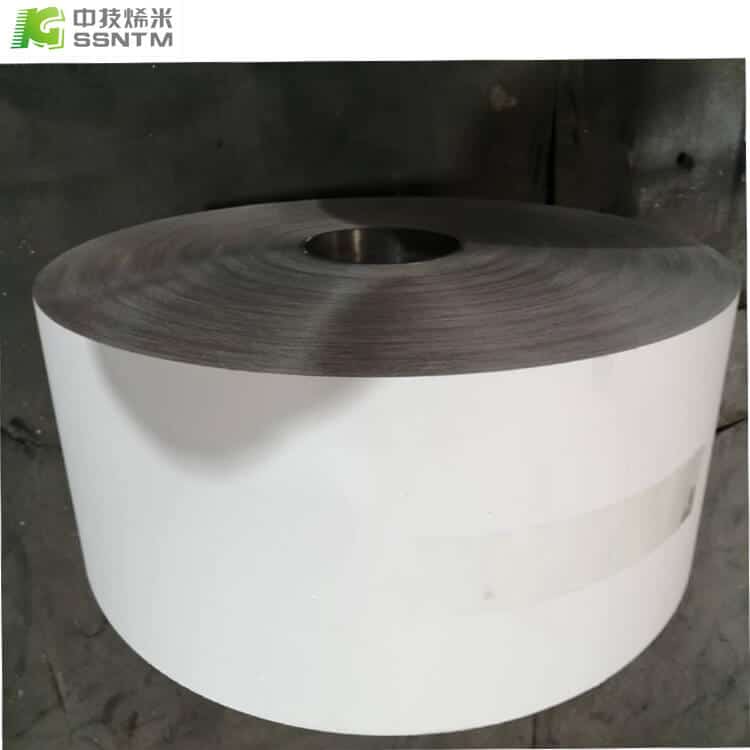

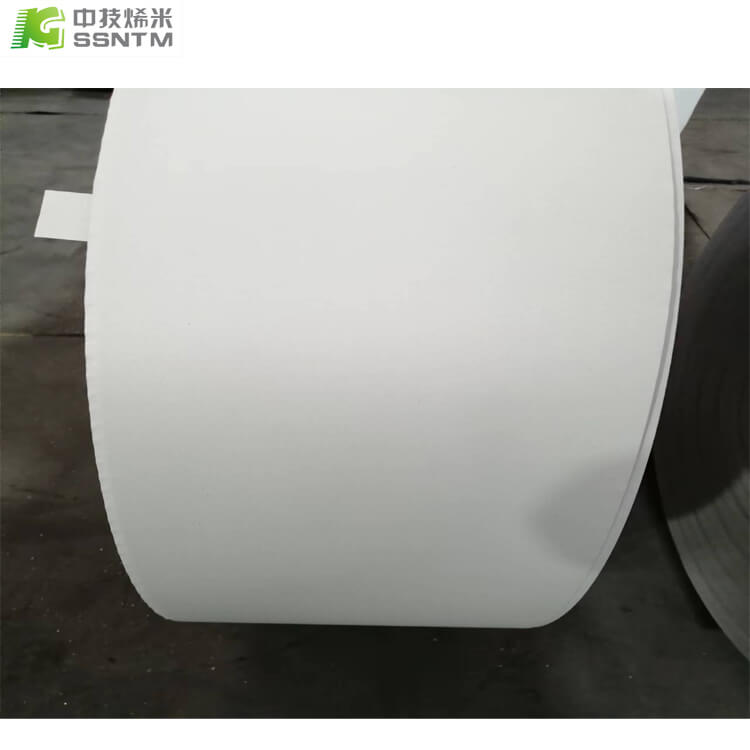

The manufacturing method of the molecular sieve aluminum foil used in air treatment systems includes steps such as selecting aluminum foil, coating cross-linked resin on aluminum foil, coating molecular sieve, and drying. The manufacturing method of the molecular sieve aluminum foil of the present invention has simple process and low cost; the manufactured molecular sieve aluminum foil has strong adsorption capacity, high strength, high heat exchange efficiency, and good anti-mold function, and can be used in various air treatment systems such as air exchange and HVAC, especially in air or petrochemical media at temperatures of -40~250 ℃.

It has been widely recognized that the use of molecular sieve materials to form an open skeleton structure on the rotating wheel of the air exchange system can absorb water molecules in the air for insulation, energy conservation and air purification. However, the molecular sieve materials adhered to aluminum impellers in existing technologies have poor adhesion, low moisture absorption, and poor durability,

In addition, in order to improve the life of the ventilation system, reduce power consumption, improve ventilation quality, and improve air exchange efficiency, the industry is also constantly trying to improve the performance of heat exchange materials.