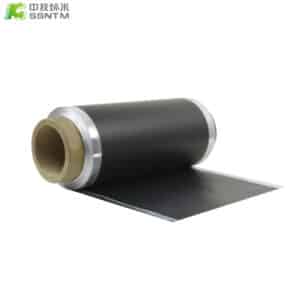

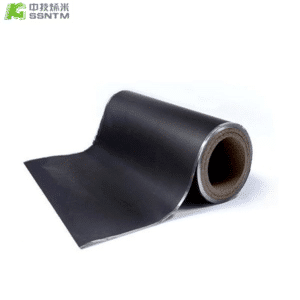

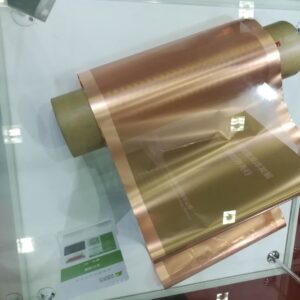

Description

The product is designed as a new type of aluminum foil current collector with uniform coating of graphene on its surface. Based on the excellent electrical conductivity and two-dimensional laver structure of graphene, the ultra-thin layer with a thickness of less than 0.5pm on the surface of aluminum foil has high electrical conductivity, which significantly reduces the interface resistance. and thus improves the adhesion between active materials and aluminum foil. Such a current collector is beneficial to the rate capability and cycle life of battery and supercapacitors. Its comprehensive performance is much better than those of other aluminum foils based on conventional carbon materials. it can replace traditional aluminum foil and corrosion aluminum foil for Li-ion batteries and supercapacitors.

Application Areas:

Li-ion Batteries

Supercapacitors

Specifications & parameters:

Appearance: Dark gray coating.

Coating Thickness (double side)/um: Typically 0.5

Areal density (double side)/mg cm-2: 0.04~0.1

Usage Instructions:

GC-foil can be directly used as current collector in Li-ion batteries or supercapacitors.

GC-foil is suitable with different coating methods. When coating, the humidity should be controlled below 30%.

When using ultrasonic welding to weld the tab on, it is suggested to set the power 10% higher than that for ordinary aluminum foil.

It is highly hygroscopic. Do not open the vacuum package before use. Once opened, it should be properly stored in a vacuum environment at room temperature after vacuum drying at 40-60C.

Features

Micro-porous aluminum foil fluid collectors are designed for use in solar thermal applications. They are made from a special type of aluminum foil that has been processed to create a micro-porous structure. This structure enhances the absorptivity of the aluminum foil, which results in greater efficiency in solar energy conversion. Here are some key features of micro-porous aluminum foil fluid collectors: 1. High thermal conductivity: Aluminum has good thermal conductivity, which means that it can quickly transfer heat from the absorber plate to the fluid circulating in the collector. This results in greater heat transfer efficiency and faster heating of the circulating fluid. 2. Improved absorptivity: The micro-porous structure of the aluminum foil enhances its absorptivity, which results in greater efficiency in solar energy conversion and higher thermal efficiency of the collector. 3. Durable: Aluminum is a durable material that can withstand harsh environmental conditions, which ensures that the collector will have a long lifespan and require minimal maintenance. 4. Lightweight: Aluminum is a lightweight material that is easy to handle and install, which makes the collector relatively easy to transport and install. 5. Corrosion resistant: Aluminum is highly resistant to corrosion, which ensures that the collector will maintain its function and aesthetic appearance over time. 6. Eco-friendly: Aluminum is a recyclable material, which makes micro-porous aluminum foil fluid collectors an environmentally friendly choice for solar thermal applications. Overall, micro-porous aluminum foil fluid collectors offer several advantages for solar thermal applications, including high thermal conductivity, improved absorptivity, durability, lightweight design, corrosion resistance, and eco-friendliness. These features make micro-porous aluminum foil fluid collectors an effective solution for solar thermal applications, particularly in flat plate solar collectors.