Description

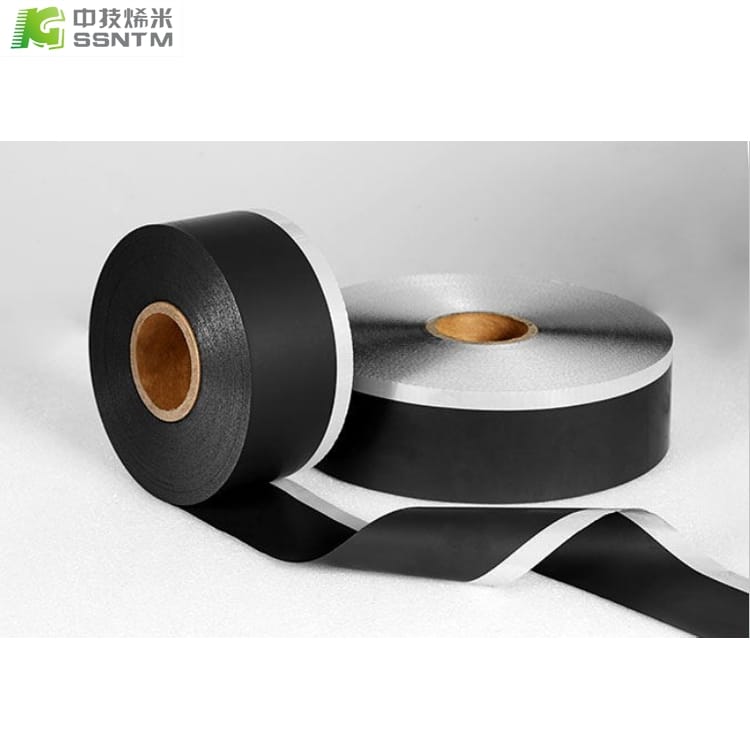

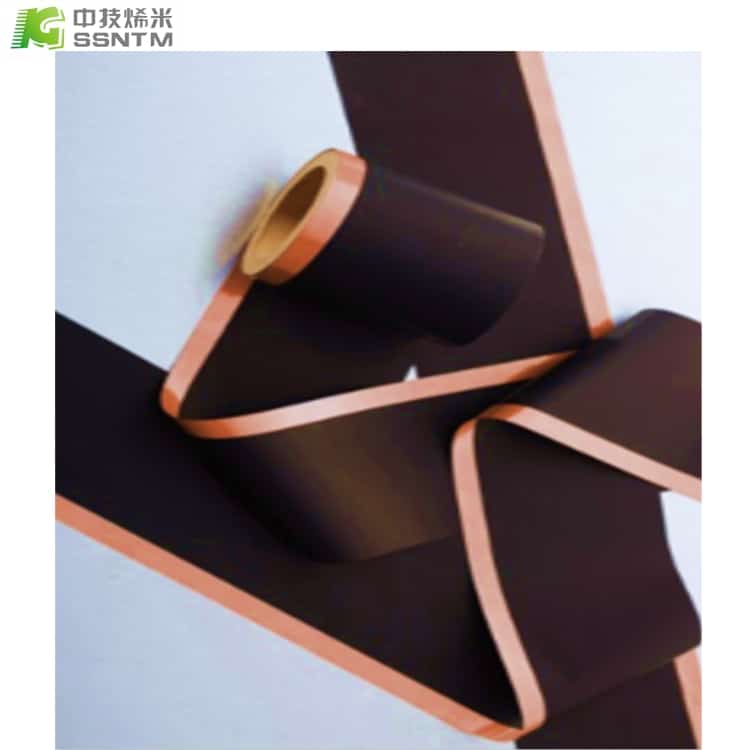

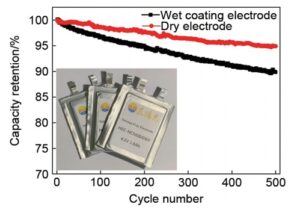

Dry coating electrode technology is one of the advanced manufacturing technologies of semi-solid and solid state lithium ion battery and solid state supercapacitor, in which the dry roll pressing process is the key. The continuous dry rolling process independently developed by our company only needs to form a dry electrode film with high density and uniform surface with evenly mixed electrode materials through multi-stage rolling, and then combine with current collector hot pressing to form an electrode sheet with dense structure and uniform thickness.

The difference between the dry process of electrode coating technology and the traditional wet process of electrode coating technology is that the wet method requires the use of solvents. The process is to mix the negative and positive electrode material powder with the solvent, and then apply it to the metal current collector to dry. The dry method does not require a solvent, and the electrode material powder is directly pressed onto the metal current collector to form the electrode. The binder exists in the fiber state, and the contact between the activated carbon particles and the conductive particles is closer. Compared to the wet process, dry electrode manufacturing does not require a large plant footprint to dry the solvent, greatly reducing the capital and labor costs required by the plant, and is more environmentally friendly.