Description

Surface modification of battery collector using functional coatings is a breakthrough technological innovation.The modified copper foil is a functional layer which is coated on the surface of copper foil with a variety of conductive materials or one of them,forming a fine two dimensional or multidimensional conductive network structure, and then collocating the conductive resin suitable for water system.Through the combination of theoretical simulation calculation and many experiments the optimal ratio structure and process strip are found out.Piece.The process can make the coating thickness thinner the coating resistance lower and the adhesion ability stronger in order to effectively improve the electrochemical performance and product stability of lithium battery especially for silicon carbon battery system.

Advantage:

◎ Improve the surface tension, and increase the adhesion between the Cu foil and the active material.

◎ Reduce the amount of binder in the electrode, increase the energy density and cycle life of the battery.

◎ Protect the Cu current collector, Prevent corrosion and oxidation of copper foil surface.

◎ Reduce interface resistance and reduce battery internal resistance.

◎ Decrease polarization and improve the rate capability and specific capacity of the electrode material.

◎ Mitigate exothermal reactions and enhance the battery safety.

◎ Improve the production stability and reproducibility, and raise the pass rate of the cell;Increase the consistency and cycling life of the cell, and lower the cost of the production.

Application:

◎ Lithium-ion batteries for electric vehicles and energy storage(Si/C)

◎ Lithium-ion batteries for 3C productions (Si/C)

◎ Lithium ion battery in water system.

Product properties:

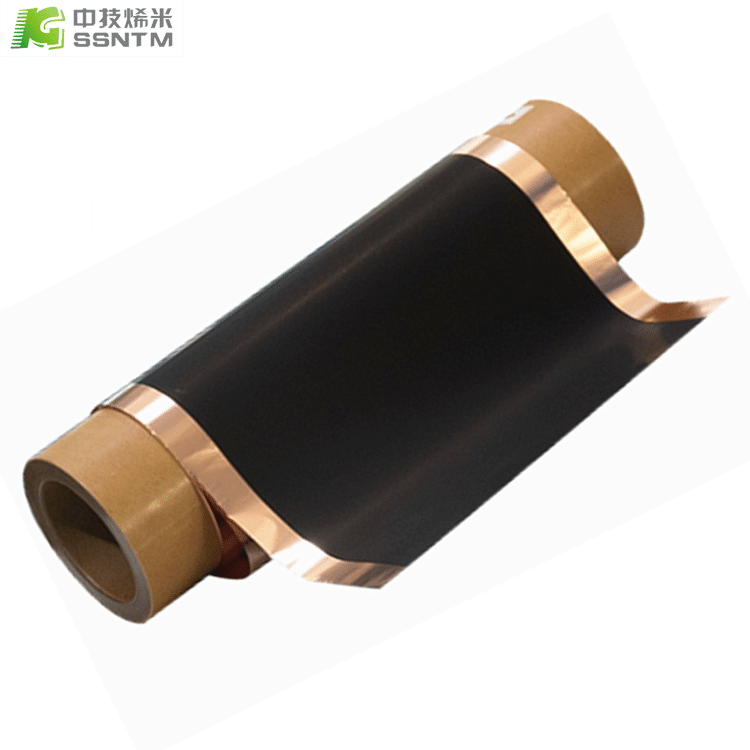

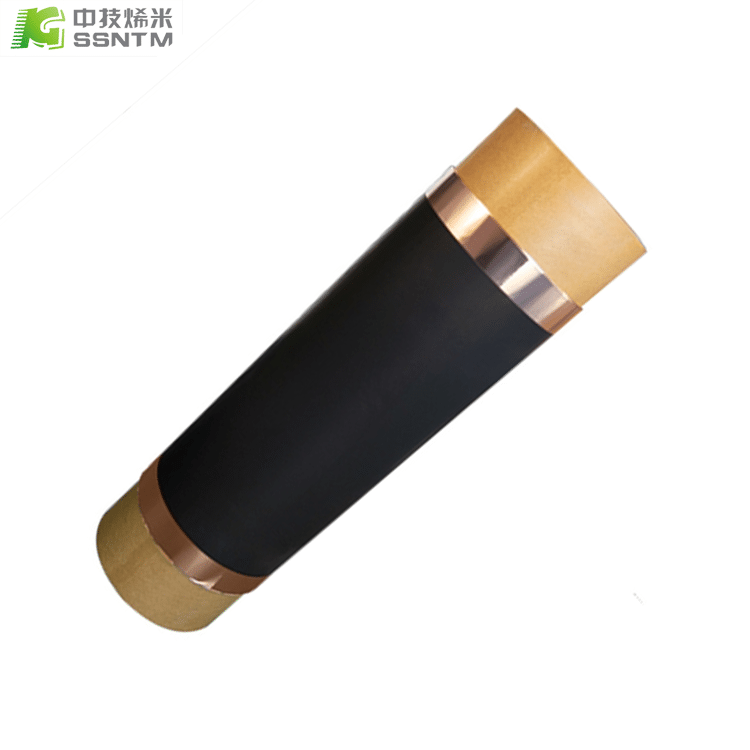

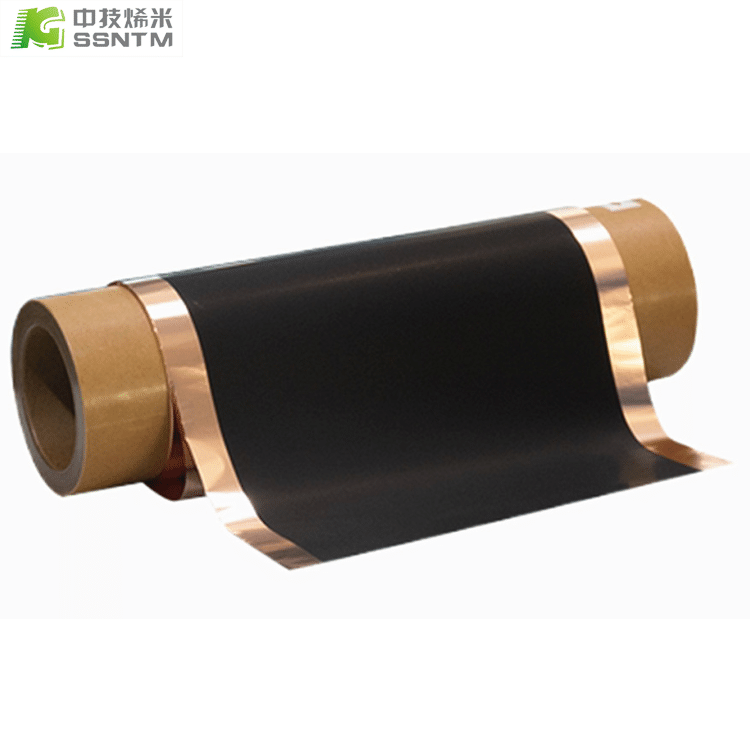

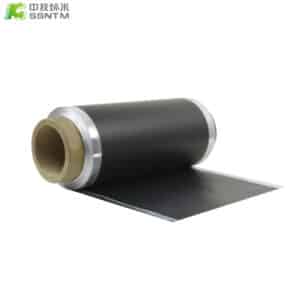

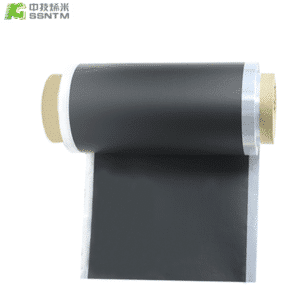

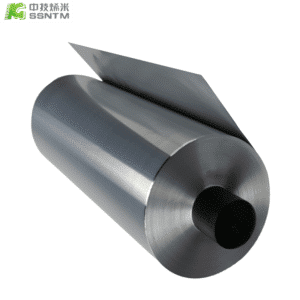

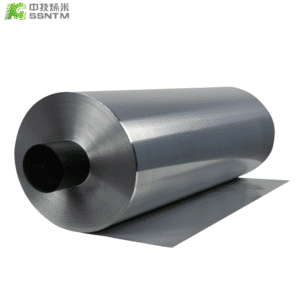

Color: black, gray

Base material: aluminum foil, copper foil

Base material thickness: 10-20 μm

Coating method: single coating, double coating

Effective coating width: customized

Material width: customized

Inner diameter of pipe core:76mm

Packing: wooden case

Origin: Foshan