The Main Production Process of Composite Copper Foil

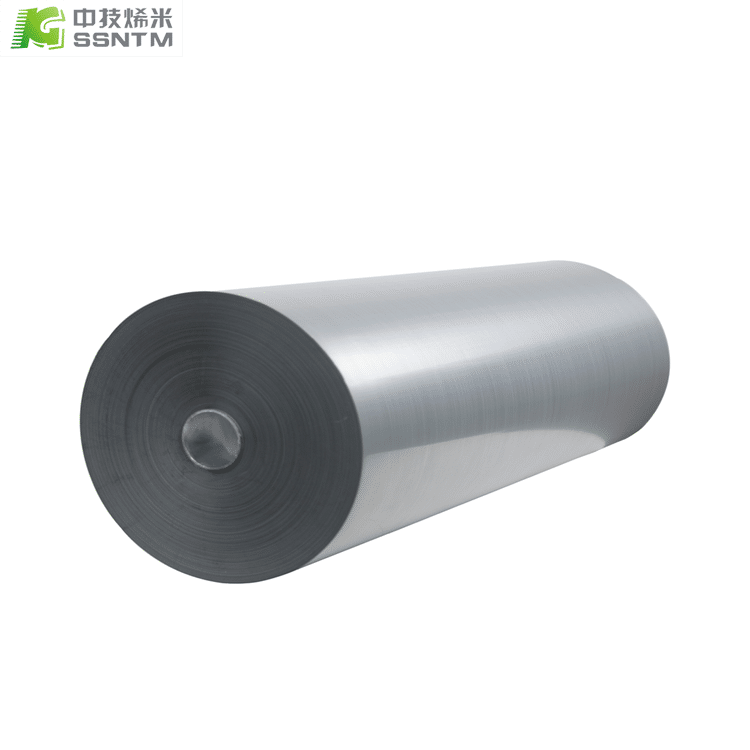

High strength corrosion foil

Composite copper foil is a new application in the lithium battery industry, but its essence is the metallization of non-metallic materials. Similar products/technologies have been widely used in other industries, including electromagnetic shielding materials, ITO coatings, copper clad plates, etc.

The production process of copper composite foil mainly includes one-step, two-step and three-step methods.

The one-step method is direct chemical deposition or magnetron sputtering on the surface of polymer film to form a copper metal layer;

The two-step method is magnetron sputtering+water electroplating;

The three-step method is magnetron sputtering+evaporation+water electroplating.

Considering the cost and efficiency, the current mainstream process for composite copper foil is the two-step method.

Considering the cost and bonding strength with copper, PET film is selected as the membrane material.