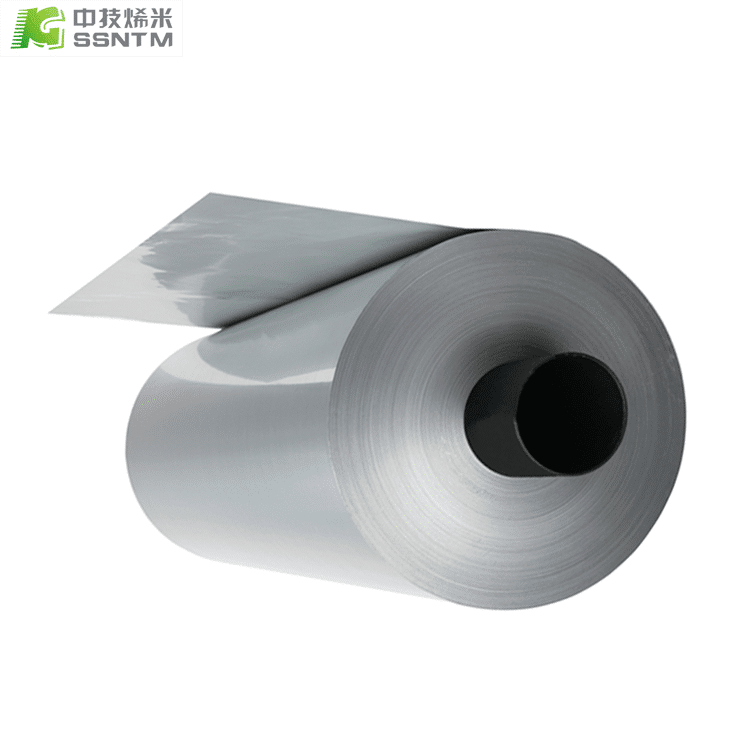

The aluminum plastic film is an important component in the manufacturing of lithium-ion batteries. The production process of aluminum plastic film for lithium batteries includes the following steps:

Preparation of the base material: PET (Polyethylene Terephthalate) film is coated with a layer of aluminum. The base material is then cleaned, polished, and treated to ensure proper adhesion.

Coating of glue: A layer of glue is coated on top of the aluminum layer with a laminating machine. The glue layer helps in securing the aluminum layer.

Placement of separator: The separator is a thin, porous material that prevents the electrode from coming into contact and short-circuiting. The separator is placed on top of the glue-coated aluminum layer.

Addition of active materials: The active materials, such as cathode and anode, are coated onto the separator using a coating machine.

Stacking process: Once the active materials have been coated, the sheets are stacked together sequentially to form a cell.

Sealing: The cell is sealed using a heat sealing machine to prevent any leakage.

Final inspection: The final assembled battery is put through rigorous tests to ensure it meets the specified requirements.

The aluminum plastic film for lithium-ion batteries is a vital component that ensures the proper functioning of batteries. Proper quality checks and testing ensure that the film meets the required specifications and helps in delivering a high-performance battery.