Application Of Copper Foil In Flexible Circuit Board

Copper foil is widely used in flexible circuit boards (also known as flex PCBs) due to its excellent electrical conductivity, thermal conductivity, and mechanical properties. Here are some specific applications of copper foil in flexible circuit boards:

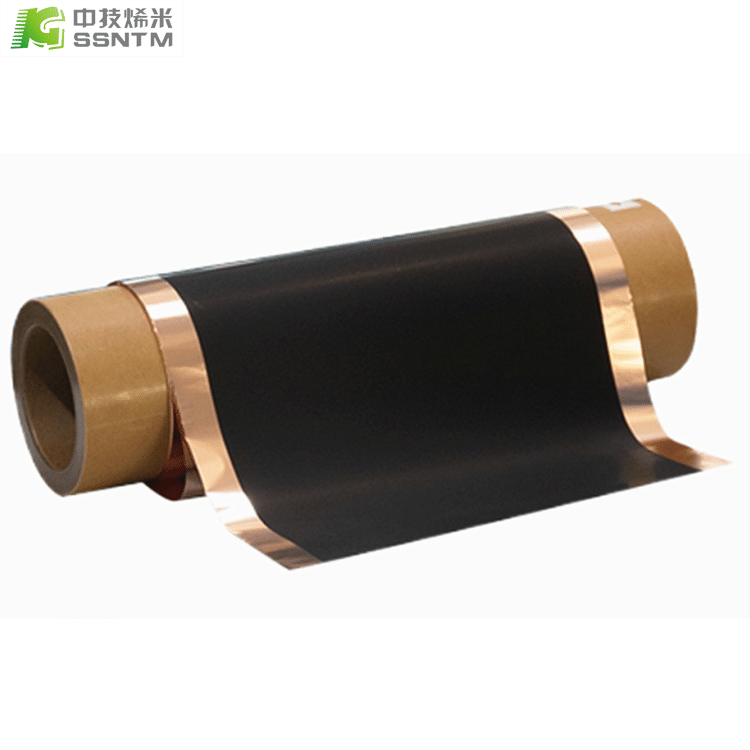

Conductor layer: Copper foil is used as the main conductor layer in flexible circuit boards, providing excellent electrical conductivity for the circuit. Copper foil is preferred over other conductive materials due to its low resistivity, high tensile strength, and good solderability.

Ground plane layer: Copper foil is also used as a ground plane layer in flexible circuit boards to provide a low-impedance path for electrical signals and to reduce electromagnetic interference (EMI).

Shielding layer: Copper foil can also be used as a shielding layer to protect the circuit from external EMI and to prevent signal interference between different components of the circuit.

Adhesive layer: Copper foil is often laminated with a layer of adhesive to provide a strong bond between the copper and the flexible substrate material, such as polyimide. The adhesive layer also helps to improve the mechanical stability of the circuit.

Etching mask: Copper foil is used as an etching mask during the manufacturing process of flexible circuit boards. The copper foil is selectively removed from the substrate material using a chemical etching process to create the desired circuit pattern.