When you first contact a lithium-ion battery, you will have the following question: Why do the positive electrode choose aluminum foil as the current collector, and the negative electrode choose copper foil as the current collector? What is the function of collecting fluid?

The function of collecting fluid is mainly to connect the powdery active substances through coating, collect and output the current generated by the active substances, and input the electrode current to the active substances. The requirements for the purity of the collector are high, the conductivity is good, the chemical and electrochemical stability is good, the mechanical strength is high, and it can be combined with the active substances of the electrode firmly.

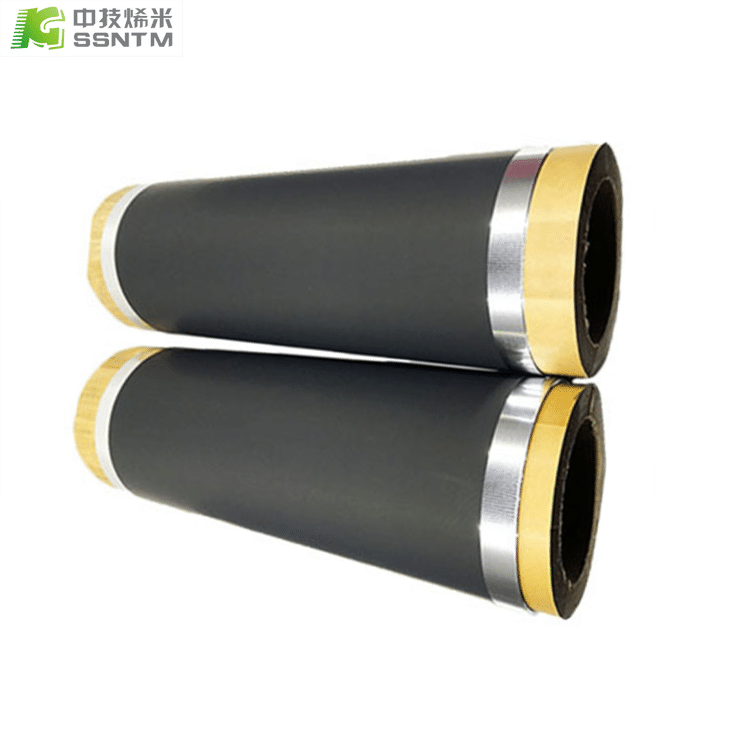

For graphene-coated aluminum foil supercapacitor power battery

Lithium electric collector usually uses copper foil and aluminum foil. Because the copper foil is easy to be oxidized at high potential, it is mainly used for the negative electrode with low potential, and the thickness is usually 6-12 μ m。 The corrosion problem of aluminum foil is serious at low potential, which is mainly used for positive current collector, and the thickness is usually 10-16 μ m。 The impure composition of the fluid collector will cause the surface oxide film to be not dense and cause pitting corrosion, and even generate LiAl alloy.

A layer of oxide film can be formed on the surface of copper and aluminum: the oxide layer on the surface of copper is a semiconductor, and the electrons can conduct, but too thick the oxide layer will lead to high impedance, while the oxide layer on the surface of aluminum is an insulator, and cannot conduct, but when the oxide layer is very thin, the electronic conductivity can be achieved through the tunnel effect, and when the oxide layer is thick, the conductivity is very poor. Therefore, it is better to clean the surface of the fluid collector to remove oil and oxide layer before use.